Punch bending processing of hardware stamping parts

Send Inquiry

Punch bending processing of hardware stamping parts is a common technique used in the manufacturing of hardware stamping parts. This process involves using a punch press to bend metal sheets into the desired shape.The first step in punch bending processing is to design the tooling for the specific part being manufactured. This includes creating a punch and die set that will accurately bend the metal sheet to the desired angle and shape.Once the tooling is prepared, the metal sheet is placed into the punch press and the bending process begins. The punch press applies force to the metal sheet, causing it to bend around the die. The angle and shape of the bend are controlled by the design of the tooling and the settings of the punch press.Punch bending processing is a precise and efficient method for creating hardware stamping parts with complex shapes and angles. It allows manufacturers to produce high-quality parts with tight tolerances and consistent results.In conclusion, punch bending processing is an essential technique in the manufacturing of hardware stamping parts. It provides a cost-effective and reliable method for creating parts with intricate shapes and angles, making it a valuable tool for the industry.

Product Description Picture of Punch bending processing of hardware stamping parts

Product Description of the Punch bending processing of hardware stamping parts

The size and material can be customized according to your needs!

Festures of the Punch bending processing of hardware stamping parts

1.Good Quality: High-grade materials ensure durability and longevity.

2.High Efficiency: Streamlined manufacturing processes lead to faster production times.

3.Low Price: Cost-effective due to efficient material use and production techniques.

4.Safe and Reliable: Designed to meet safety standards and provide consistent performance.

5.Versatile Applications: Suitable for a wide range of furniture designs and styles

About us

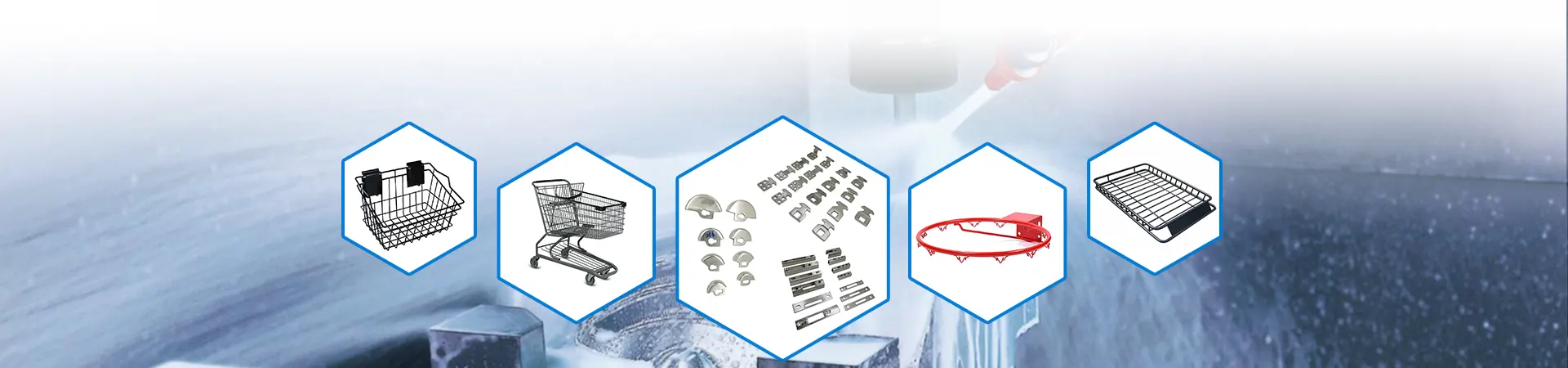

Our company is specialized in handling the export business of hardware products, including Wall Storage Basket, Shopping Carts, Mini Basketball hoop, Plant Stand, Display Rack, Shoes Rack, Kitchen Holder, Fruit Basket, Billboard ect. We have our own factory that have been experiencing for many years.

-Original design:

We have our original designs with various types of products for you to choose.

-Customization:

We can produce according to customer's own design.

Our company is specialized in handling the export business of hardware products, including Wire Storage Basket, Hand Carts, Mini Basketball hoop, Plant Stand, Display Rack, Storage Holder, Fasteners, Stamping parts. We have our own factory that have been experiencing for many years.

-Original design:

We have our original designs with various types of products for you to choose.

-Customization:

We can produce according to customer's own design.

FAQ

1. Supplier type: Manufacturer.

2. Products: basketball hoops, storage baskets, shopping carts, flower pots

3. Average capacity: 8000pcs/month.

4. OEM/ODM service: Yes.We can produce the product under your brand name, also the size can be changed as your requirement.

5. Delivery time: About 15-30 working days.

6. Payment terms: T/T 30%, blance paid before shipping(Western Union, Cash is OK).

7. Port of loading: Ningbo/Shanghai.

8. Sample fee: we just charge the samples based on EXW price, and we will return the samples fee during the next order.

Send me an inquiry for more new products.

Contact us:

Email:sales02@junmetal.com

Whatsapp:+86 18358310729

Wechat:junmetal_hardware